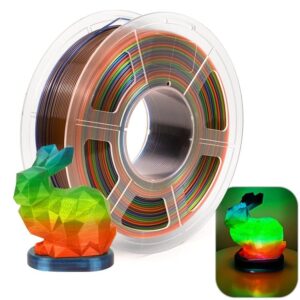

Kexcelled K7 95A TPU 3D Printer Filament

8.250 د.ك

SKU

N/A

Categories Kexcelled, TPU

Tags 3D Filament Al Jahra, 3D Filament Dammam, 3D Filament Dubai, Kexcelled 3D Filament Kuwait

Feature Introduction:

TPU 3D Filament is an elastomer consumable with high performance and great stability for FDM/FFF. Ten kinds of TPU materials present different characteristics in hardness, maximum deformation, density, and abrasion, thus meeting multiple needs of printed products. The 95A, 55D, and 77D materials of medium and high hardness meet the printing requirements of a wide range of models. The elongation of TPU K7 75A with low hardness and high rebound can reach 800%.

Basic Physical Properties:

| TPU K7 95A | Printed copy (horizontal printing of sample, 100% linear filling) | Injection molded parts | Test standards |

| Density (g/cm3) | 1.14 | ISO 1183 | |

| Melt flow rate (MFR) 1 | / | ISO 1133 | |

| Heat deflection temperature(HDT)2 | / | ISO 75 | |

| Tensile strength (MPa) | >18 | ISO 527 | |

| Elongation at break(%) | >1240 | ||

*1. Test condition: temperature (T)=210 ℃; Mass (m)=10kg.

*2. Test condition: bending stress=0.45MPa; Heating rate=130 ℃/h.

*3. Test condition: load=10N; Heating rate=120 ℃/h.

| Color | Black, Blue, Orange, Red, Silver, White, Yellow, Peacock Blue |

|---|

Related products

-

3D Filament

Kexcelled PLA K5G Dual Colors

5.800 د.ك This product has multiple variants. The options may be chosen on the product page -

3D Filament

Kexcelled K5 PLA 3D Printing filament

6.250 د.ك – 7.750 د.كPrice range: 6.250 د.ك through 7.750 د.ك This product has multiple variants. The options may be chosen on the product page -

3D Filament

Kexcelled K5 SILK / High Gloss PLA 3D Filament

6.850 د.ك This product has multiple variants. The options may be chosen on the product page